Gantry Cranes: Efficient Heavy Lifters Revolutionizing Industrial Operations

Introduction:

Gantry cranes are powerful and versatile machines that have transformed the landscape of modern industrial operations. These towering structures equipped with large moving arms and trolleys enable efficient lifting, transporting, and positioning of heavy loads within a wide range of sectors. This article explores the fascinating world of gantry cranes, their types, applications, and the significant role they play in various industries.

What are Gantry Cranes?

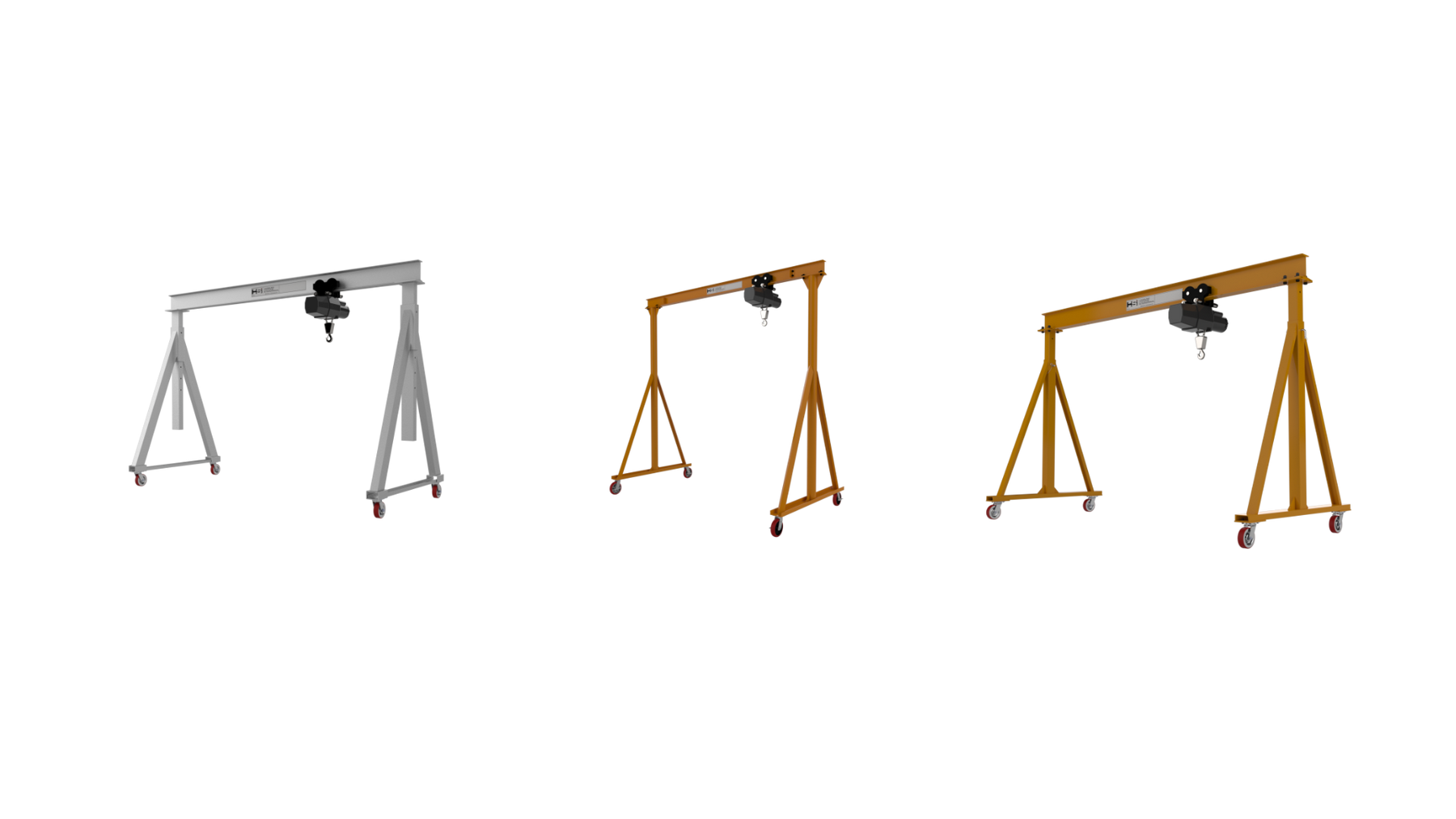

Gantry cranes, also known as portal cranes, are industrial lifting machines characterized by their overhead beams supported by legs that run on rails or wheels. They come in various sizes, from small portable units to massive structures capable of lifting hundreds of tons. The primary components of a gantry crane include the main beam, end carriages, trolleys, hoists, and control systems.

Types of Gantry Cranes:

a) Full Gantry Cranes: These cranes feature legs on both sides of the span, allowing them to move freely along a rail or wheel system. They are commonly used in shipyards, construction sites, and container terminals.

b) Semi-Gantry Cranes: Semi-gantry cranes have one end carriage supported by legs, while the other end moves on a runway attached to an existing structure. They are ideal for situations where one side needs to be supported by a building or other fixed structure.

c) Portable Gantry Cranes: These lightweight and versatile cranes can be assembled and disassembled easily, making them suitable for temporary applications in workshops, warehouses, and construction sites.

Applications of Gantry Cranes:

a) Ports and Shipping: Gantry cranes are indispensable in container terminals for loading and unloading containers from ships. Their high lifting capacity and ability to move along rails enable efficient cargo handling, reducing turnaround times and increasing productivity.

b) Construction Industry: Gantry cranes are utilized in construction sites to lift heavy materials such as steel beams, precast concrete elements, and machinery. Their mobility and flexibility make them invaluable for erecting structures and handling large components.

c) Manufacturing and Warehousing: Gantry cranes play a crucial role in manufacturing facilities and warehouses for moving heavy loads, positioning machinery, and organizing inventory. They enhance productivity, streamline operations, and ensure worker safety.

d) Mining and Energy: Gantry cranes are employed in the mining industry for lifting and transporting massive equipment and materials. They are also utilized in power plants for maintenance tasks, such as replacing turbines and handling heavy components.

Advantages of Gantry Cranes:

a) High Lifting Capacity: Gantry cranes are capable of lifting extremely heavy loads, making them essential for handling large and bulky objects in various industries.

b) Versatility: These cranes can be customized with different attachments and lifting mechanisms to suit specific applications, making them adaptable to different tasks.

c) Mobility: Gantry cranes can move along rails or wheels, allowing them to cover a wide area and access various workstations within a facility.

d) Improved Efficiency and Safety: By mechanizing the lifting process, gantry cranes reduce the risk of manual handling injuries and enhance overall operational efficiency.

Conclusion:

Gantry cranes have revolutionized the way heavy lifting is performed in industries worldwide. Their robust construction, lifting capabilities, and versatility make them an integral part of port operations, construction sites, manufacturing facilities, and more. With ongoing advancements in technology, these remarkable machines continue to evolve, further enhancing productivity and safety standards in the industrial sector.